PROCESSINGS

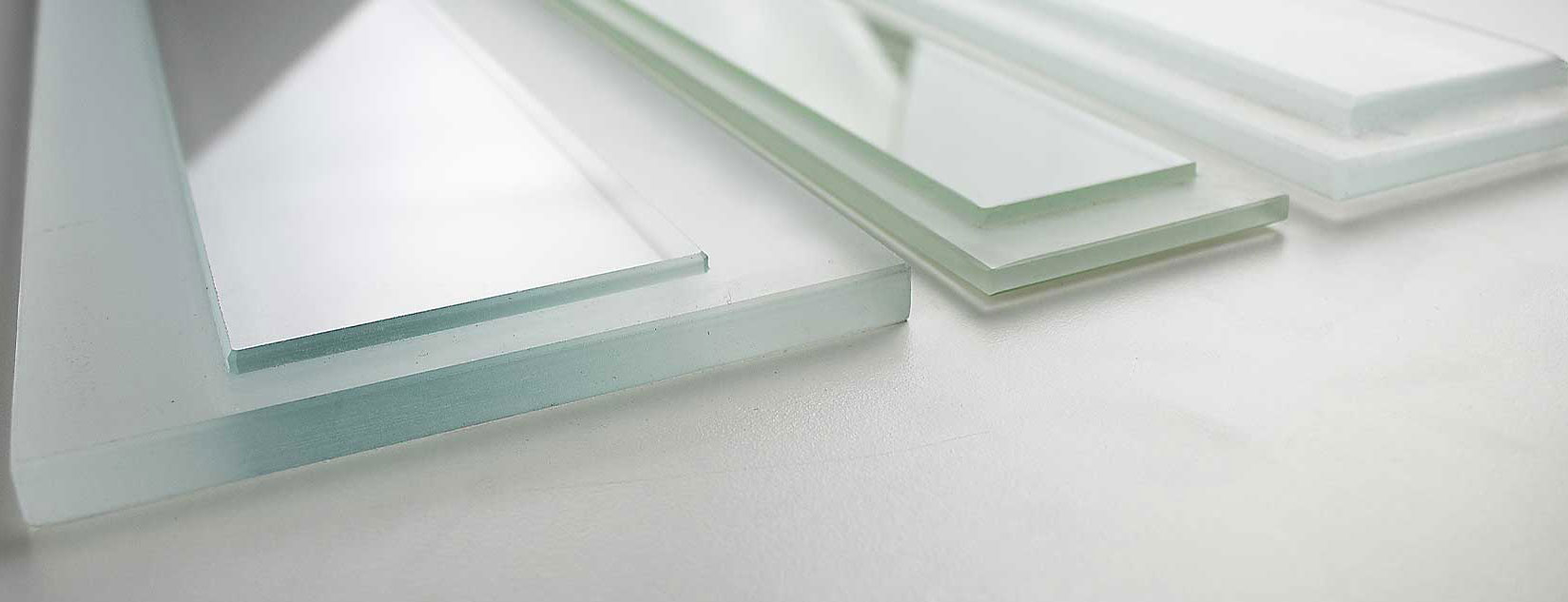

CUT

Glass cutting in large quantities is possible by using a professional cutting bench on which we place the glass plate, then cutting it with automated machinery and obtaining a linear or shaped glass that accurately respects the set measurements.

GRINDING

Grinding involves the removal of material from the cutting edge of a glass with the use of diamond wheels of rough or fine grain. This procedure eliminates the sharp part and the roughness allowing to obtain pieces exactly to measure in the order of a tenth of millimeter. By means of this operation it is possible to obtain different types of finishes (raw or lucid) and various edge profiles (round, flat, rim).

CNC

Our numerical control machines perform contouring, milling, drilling, bevelling and engraving on glass. In detail, the contouring is the perimeter grinding of the edges, while by the milling grooves and hollows are made on the glass profile. It is also possible to make rough, polished and countersunk holes of different sizes by drilling. The bevelling thins and polishes the perimeter parts of the plate in order to obtain an original frame effect on the edge, ideal for mirrors and shop windows. Finally, the engraving on the glass surface of writings, logos and drawings allows to customize the product as desired.

SERIGRAPHY

Serigraphy consists in the application of a thin layer of paint on the surface of the glass to create drawings and writings for both artistic and functional purposes. The painted glass thus takes on a new image and has a greater visual impact than the typical neutral shade of the material. Serigraphy can be applied on different sizes and in different colors based on customer's specifications.

TEMPERING

Tempering is a particular heat treatment that is carried out by placing the glass inside an oven in which it will be heated up to a temperature of about 650 °C. By the heat of the oven the material reaches a state close to softening and it is exactly at this moment that an instant cooling of the glass must be caused. This process gives to the piece a higher surface mechanical resistance and guarantees safety in case of breakage by reducing the glass into small non-sharp fragments.

SANDBLASTING

Sandblasting consists of a surface abrasion of the glass, exposing it to a very powerful jet of sand and air in order to erode the surface. This ancient technique allows to create both functional and purely aesthetic decorations and designs. It is important to underline that this decorative process does not diminish the traditional characteristic of glass: in fact, the light continues to pass, creating an opacifying effect.